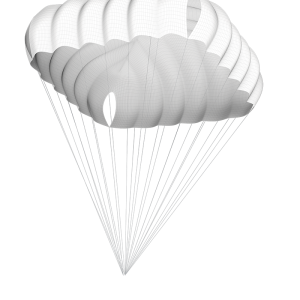

High Adventure Beamer 3

$1,095.00 – $1,650.00Price range: $1,095.00 through $1,650.00

In 1995 the Beamer opened a new chapter in the history of paraglider reserve parachutes. Our Rogallo concept changed the scene for ever, and the Beamer 1 still waits, ready for action, in many harnesses. In 2010 the Beamer 2 set another benchmark for steerable reserves. Its proven concept, new features and improved qualities convincingly established the Beamer 2 in the market. The Beamer 3 builds on the best features of the Beamer 2. A completely redeveloped Beamer 3 riser system improves opening, operation and installation – the success story continues!

Description

Fast opening

Opening time is the most important reserve criteria. If a reserve has to be thrown at low altitude – and that is often the case – a single second can make all the difference. The Beamer 3’s special shape and particular folding technique help it open up to 50% faster than normal round canopies; the Beamer 3 is setting EN Test records.

Stable flight

When developing a Rogallo our main focus is how it works with the paraglider. After reserve opening the paraglider can stay attached (the usual emergency situation – no quick release/cutaway). Here the Beamer 3 really plays its trump card, and is far superior to the smaller models on the market in this respect. After a fast opening the Beamer 3 quickly takes control. It goes into very slow forward flight and therefore does not encourage the paraglider to disturb it. The Beamer 3 achieves Its stability, among other things, by its low wing loading. This accords with our recommendation: Don’t put your trust in anything under 40 m2.

As a special feature we elected to further develop the braked opening configuration for the Rogallo – successfully applied to the Beamer 2. This results in even less forward speed and provides what most pilots need – the advantages of a round canopy’s vertical flightpath, plus those of a steerable forwards-flying Rogallo. For example, if the Beamer opens alongside a rock face, or in strong wind, its initial descent will be almost vertical. Then, after its steering lines have been activated, the Rogallo’s forward speed can be used. If the pilot has enough height he can then steer the Beamer 3 away from danger (e.g. rocks, water, buildings etc.).

The braked opening configuration automatically includes another important effect: what is known as ‘downplaning’ is effectively prevented. This scissoring problem happens when paraglider and reserve (round canopies too) both develop forward speed while pulling against each other, and both head straight downwards. This raises the sink speed markedly, and the risk of injury dramatically. The Beamer 3’s pre-braking and its large area oppose this: the braked Rogallo surface refuses to be accelerated in this way.

Low sink speed

Assuming a reserve is open with its paraglider in a stable situation the next most important thing is sink speed. Low wing loading and modest forward speed give the Beamer 3 an unrivaled low sink rate. The EN certification authority has confirmed a sink rate of 3.9 m/s at maximum weight of 130 kg (without the paraglider). The additional braking effect of a paraglider reduces this value to less than 3m/s.

Steering and flying forwards – the Beamer’s specialty!

Paraglider under tow: In real-life reserve-throwing situations the paraglider can become a massive problem. In many cases the paraglider is already collapsed, both during and after reserve opening, and therefore prevented from flying. Here the Beamer 3 descent is a pure pleasure. The canopy reacts immediately to steering commands and sinks at its slowest rate. When the reserve is thrown while the paraglider is flying normally, such as during SIV training, the descent characteristics of both Rogallo and round reserve can be affected. If the paraglider reopens itself during a reserve descent it can easily be prevented from flying by B-stall, or reefing in. This will greatly improve steerability. Countless examples in practice confirm the problem-free behavior of all Beamers in every possible situation.

Paraglider tangled up in the Rogallo lines: Here pilots with a cutaway system can fully appreciate the Beamer 3’s qualities. Glide performance doubles – with slightly increased sink speed. Cutaway carabiners mainly make sense in competition flying (more risk of collision) or for acro. A suitable seatbelt cutter, secured on a long bungee, would do the same job in an emergency.

Technical differences between Beamer 3 and Beamer 2

The Beamer 3 has a completely new, simplified and user-friendly riser system. This reduces the chance of twists, and makes installation easier. Packers will appreciate this: Steering line shortening for the braked opening stage is largely self-explanatory. The risers are set up for shoulder mounting. Short extensions are needed for main carabiner (front container) attachment.

Size, wing shape, lines and flying behavior of the Beamer 3 remain unchanged from the Beamer 2. Construction details and the new risers reduce the weight from (very light!) 1950 to 1785 gm for an area of 42 m2.

After 3 years’ good experience of the Beamer 2 we could assume the same performance for fabric and lines. Despite its light construction the long-lived and robust Beamer 3 can be thrown over water.

Please see High Adventure’s website for more details.

Related products

-

Skywalk Tapa X-Alps

$1,000.00 – $1,100.00Price range: $1,000.00 through $1,100.00 This product has multiple variants. The options may be chosen on the product page -

Niviuk Octagon 2

$805.00 – $1,410.00Price range: $805.00 through $1,410.00 This product has multiple variants. The options may be chosen on the product page -

High Adventure Beamer 3 Light

$1,250.00 – $1,900.00Price range: $1,250.00 through $1,900.00 This product has multiple variants. The options may be chosen on the product page -

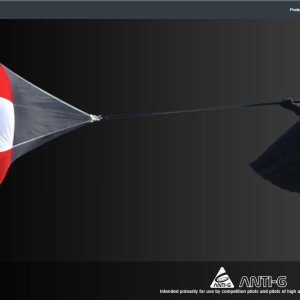

Ozone Anti – G

$206.00

Schedule Lessons

Our training season runs from the start of April until mid October. Lessons take place at our training hill in North Boulder every morning, Monday – Sunday.

Subscribe

For the latest on upcoming clinics, trips and new gear.

Copyright © 2025 Red Tail Paragliding LLC. All Rights Reserved.